tiandi@tiandicn.com / lab-glassware@tiandicn.com

+86-515-88631536 / +86 13912566435

+ 86 19551521639

Tiandilabware

Product features

It is generally made of materials such as borosilicate glass, and has good chemical stability, thermal stability and transparency. It can withstand the erosion of a variety of chemical substances, can be used under different temperature conditions, and it is convenient to observe the internal situation.

Sealing cover: It usually has a wide-edged frosted design, which fits closely with the frosted opening of the tank body. With the addition of sealing materials such as vacuum grease, it can form a good sealing effect to ensure that the desiccator remains in a vacuum state after being evacuated.

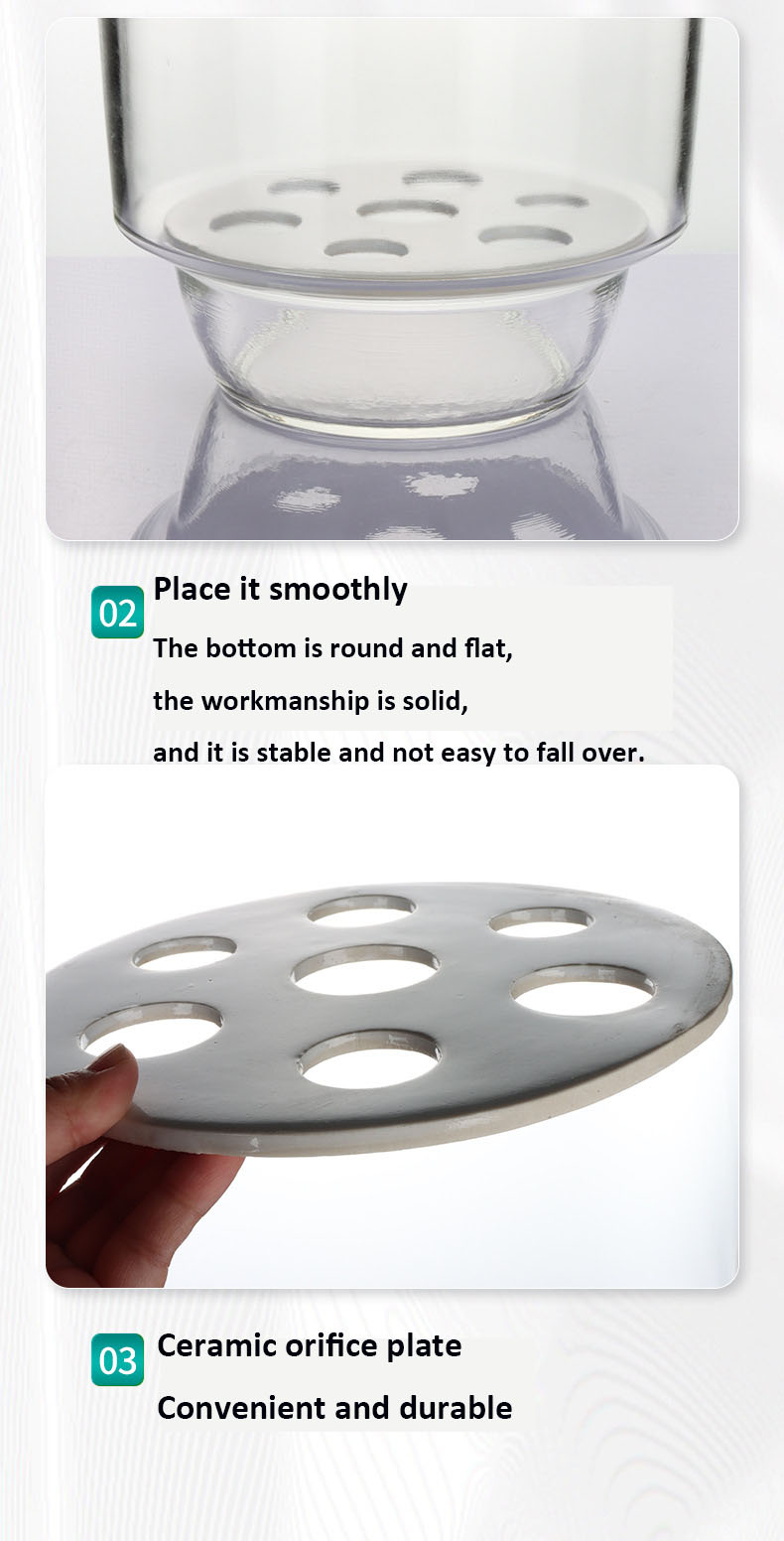

Perforated shelf: It is located inside the desiccator, generally made of ceramic or glass materials, and has many small holes on it. Its function is to place the items to be dried, so that the items can be in uniform contact with the drying environment, and at the same time, it is convenient for the circulation of air.

Air inlet valve and air extraction port: The air inlet valve is used to slowly let in air after the drying is completed, so as to balance the internal and external pressures of the desiccator and make it easy to open. The air extraction port is used to connect to a vacuum pump to extract the air inside the desiccator and form a vacuum environment.

Base: It plays the role of supporting the entire desiccator and is usually designed to be relatively stable to ensure that the desiccator will not tip over during use. Some bases can also hold desiccants inside to enhance the drying effect.

Product details

We can produce different desiccators as per customer’s requirements.We can also print your logo on the desiccators if the quantity is large,please feel free to contact us online.

Product specifications

| Item NO. | I.D. (mm) | O.D of bottom (mm) | Total height (mm) | PCS/CTN |

| 1354-150 | 150 | 95 | 220 | 4 |

| 1354-180 | 180 | 110 | 260 | 4 |

| 1354-210 | 210 | 124 | 275 | 2 |

| 1354-240 | 240 | 140 | 325 | 2 |

| 1354-300 | 300 | 170 | 355 | 1 |

| 1354-350 | 350 | 205 | 400 | 1 |

| 1354-400 | 400 | 225 | 460 | 1 |

| 1354-450 | 450 | 256 | 565 | 4 |

Product applications

Vacuum desiccator can be used in laboratories: in chemical, biological, pharmaceutical and other laboratories, used to dry experimental samples, reagents, instruments, etc. For example, drying solid samples contains moisture, removes solvent residues, etc.

Industrial production: In pharmaceutical, food, electronics and other industries,used for drying raw materials, semi-finished products or finished products. For example, dry pharmaceutical powders, food additives, electronic components, etc.

Scientific research field: In scientific research of material science and chemical engineering and other fields , it is used to dry special materials to study their properties and structural changes.

Pay attention to controlling the vacuum degree and temperature during application: During the drying process, the vacuum degree and temperature should be reasonably controlled according to the nature and requirements of the items. Excessive vacuum and temperature may cause damage to items, while too low vacuum and temperature will affect the drying effect.

Safe operation: When operating the vacuum pump and releasing vacuum, strictly follow the operating procedures to avoid safety accidents. At the same time, be careful to prevent the desiccator from being hit or dropped to avoid damaging the glass container.